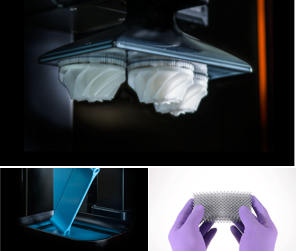

DLS (Digital Light Synthesis) enabled by Carbon’s proprietary CLIP technology, is a breakthrough process that uses digital light projection, oxygen permeable optics, and programmable liquid resins to produce parts with excellent mechanical properties, resolution, and surface finish.

| model/make | The M2 by Carbon |

| mechanism | UV curable 2-part urethane and epoxy materials |

| materials | Rigid Polyurethane, Flexible Polyurethane, Elastomeric Polyurethane, Silicone, Epoxy Cyanate Ester, or Methacrylate Prototyping Resin |

| applications | Functional production quality parts available in a wide variety of performance materials. |

| pros/cons | Functional parts with isotropic properties close to those of materials used in various traditional manufacturing processes. The greatest current limitation is the somewhat small platform size. |

How it Works

How it Works

For the first time, it’s possible to print high-resolution parts with mechanical properties like injection-molded plastics. No other additive technology delivers the combination of fit, form, and function needed to bridge the gap between prototyping and manufacturing.

CLIP is a photochemical process that carefully balances light and oxygen to rapidly produce parts. It works by projecting light through an oxygen-permeable window into a reservoir of UV curable resin. As a sequence of UV images are projected, the part solidifies and the build platform rises.

Who Uses It

Who typically uses it depends on what materials are selected. For example, RPU, or Rigid Polyurethane performs well under stress, combining strength, stiffness, and toughness. These properties make RPU particularly useful for consumer electronics, automotive, and industrial components, where excellent mechanical properties are needed. Read on for details about which materials are right for specific applications.

What Materials Does it Use?

Parts produced with the M2 have the resolution, surface finish, and mechanical properties needed for production parts. Our materials reflect a range of common injection-molded thermoplastics and our process produces isotropic parts that don’t suffer from delamination or surface porosity.

For Further Questions

Not sure if CLIP technology is right for your application? Get in touch.