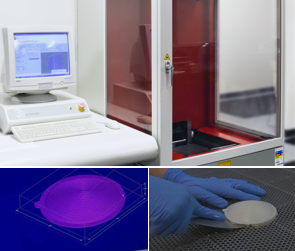

Directs a computer controlled laser on to build 3-D parts out of a photopolymer resin.

| model/make | SLA 3500 and iPro 8000 by 3DSystems |

| mechanism | Photopolymer Resin |

| materials | Accura 25 and Watershed XC 11122 |

| applications | Display parts, Accurate fit assemblies, cosmetic parts and master patterns |

| pros/cons | Capable of very fine detail and class “A” surface finishes as well as optically clear parts |

How it Works

Stereolithography (SLA) uses a computer-controlled UV laser to build 3D parts by selectively curing photopolymer resin layer upon layer. As one of the earliest commercialized 3D printing technologies, SLA is a mature and proven technology that has proven compelling for a wide variety of applications.

Who Uses It

SLA is capable of producing 100% dense parts with very fine detail. SLA parts can be sanded to a class “A” surface finish or polished to become optically clear. Example applications include display parts, fit assemblies, jigs, fixtures, gages, and master patterns.

What Materials Does it Use?

SLA materials available internally at the MSOE Rapid Prototyping Center include Accura 25 and Watershed XC 11122. Many other materials are accessible through the center via our partners.

For Further Questions

Not sure if SLA technology is right for your application? Get in touch.