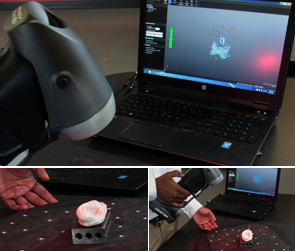

The Creaform HandyScan is an important data acquisition tool that can be utilized for many applications. This scanner is portable, quick to setup and accurate.

| model/make | HandySCAN 3D by Creaform |

| mechanism | 3D Laser Scanning |

| applications | 3D scanning is great for concept reverse engineering, design, deformation or wear analysis, legacy part restoration, prototyping, Quality Control/First Article part inspection, Complex assemble/retro fitment interference check, Alignment analysis, Tooling design, digital archiving, re-creation of historic artifacts. |

| pros/cons | The advantages of this scanner are many, including, portability, project size flexibility, accuracy, and speed. Its limitations are the required use of targeting features and line of sight access. |

How it Works

The HandySCAN 3D is a high performance portable laser scanner that is run off of a laptop. Its size and ease of operation allows us to complete many challenging projects onsite in a variety of different environments. The system works by projecting several lasers over a surface and recording the point positions in space. The positioning of the scanner is accomplished by the use of randomly placed adhesive or magnetic targets throughout the field of view, which are concurrently triangulated back to the camera and allows for the unique position of the scanner to be identified at all times.

The native export of the scanner is a .STL file which can be directly used for deviation analysis or 3D printing. Alternatively, a .STL file can also be used to recreate either a surface file such as .igs or .stp through further processing.

For Further Questions

Not sure if 3D Scanning technology is right for your application? Get in touch.